The evolution of a natural zeolite as a supplementary cementitious material for the production of conventional concretes represents a significant advancement in sustainable construction practices. Zeolites as an addition to cement in San Luis Potosi, due to their unique porous structure and chemical composition, offer potential benefits such as enhanced durability, improved mechanical properties, and reduced environmental impact.

In a previous blog we talked about the potential benefits of mixing zeolites in with cementhis study explores the effectiveness of incorporating natural zeolite into concrete mixtures, aiming to understand its influence on compressive strength and overall performance. By replacing a portion of traditional cement with zeolite, we can lower carbon emissions associated with cement production, contributing to more eco-friendly building solutions.

The findings from this research could pave the way for widespread adoption of zeolite in the construction industry, promoting sustainability without compromising on the quality and reliability of concrete structures.

Analysis:

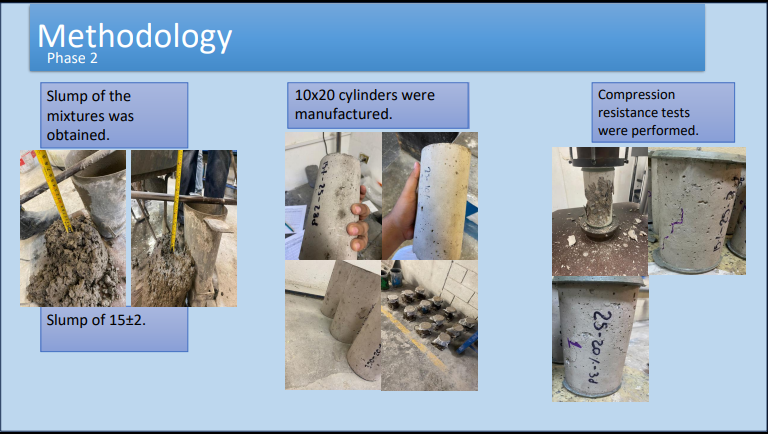

Phase 2 focused on assessing the workability and strength of zeolite-enhanced concrete. A slump test was performed to ensure the mixtures maintained a workable consistency of 15±2. Standardized 10×20 cm cylinders were cast and tested for compressive strength at various curing intervals. These tests provided reliable data on the mechanical performance of the concrete, highlighting the potential of natural zeolite as a supplementary cementitious material.

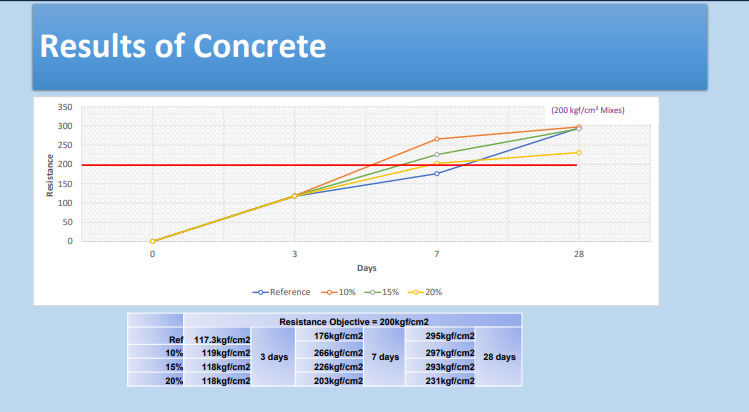

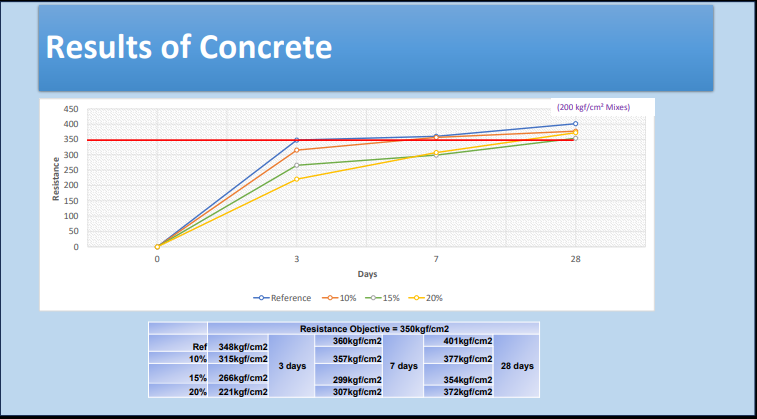

Results of Concrete (200 kgf/cm² Mixes)

The first graph shows the compressive strength of concrete with different percentages of zeolite added (10%, 15%, 20%) compared to a reference mix over 0, 3, 7, and 28 days.

Analysis:

These results indicate the effectiveness of using zeolite as a supplementary cementitious material. The target resistance for these mixes was 200 kgf/cm². The addition of zeolite seems to enhance the compressive strength of the concrete, particularly noticeable at 7 and 28 days.

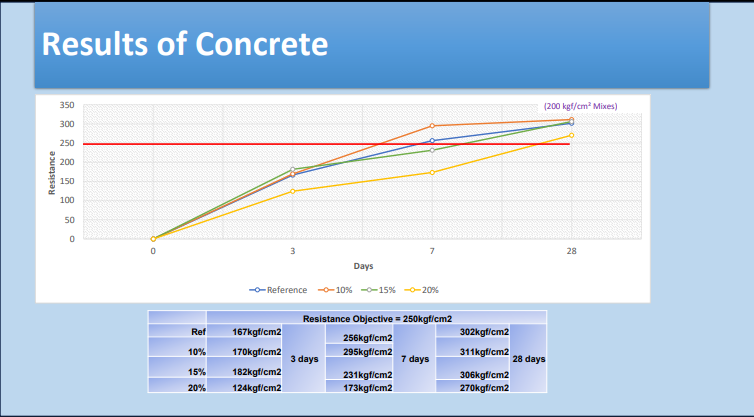

Results of Concrete (250 kgf/cm² Mixes)

The second graph presents the compressive strength data for 250 kgf/cm² mixes with varying zeolite content.

Analysis:

For mixes targeting 250 kgf/cm², the incorporation of 10% and 15% zeolite maintains or even improves the compressive strength compared to the reference, while 20% zeolite shows a slight reduction.

Results of Concrete (300 kgf/cm² Mixes)

This graph illustrates the compressive strength for 300 kgf/cm² mixes.

Zeolite as an Addition to Cement in San Luis Potosi

Analysis:

For mixes with a target of 300 kgf/cm², the results show that 10% and 15% zeolite can significantly improve the early compressive strength, maintaining or slightly decreasing by 28 days.

Results of Concrete (350 kgf/cm² Mixes)

This graph shows the compressive strength results for 350 kgf/cm² mixes.

Analysis:

For the highest target mix of 350 kgf/cm², the addition of zeolite continues to show strong performance, particularly at 10% and 20%, with compressive strengths approaching or exceeding the reference mix.

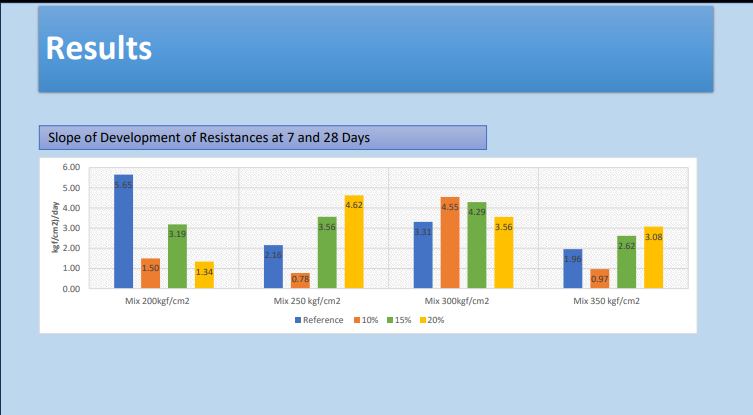

Results: Slope of Development of Resistances at 7 and 28 Days

This graph provides insights into the rate of strength gain between 7 and 28 days for different mixes.

Analysis:

The slope values suggest how quickly the concrete gains strength over time. The reference mix generally shows higher slopes, indicating faster strength gain compared to the zeolite mixes, although certain zeolite percentages still show comparable rates of development.

Performance of Zeolite Mixes Based on Reference Mix

This graph illustrates the relative performance of the zeolite mixes as a percentage of the reference mix’s strength at different ages.

Analysis:

This comparison highlights the relative improvement or decline in performance for zeolite mixes compared to the reference. The goal is to identify the optimal zeolite content that maximizes performance while maintaining or enhancing the concrete’s compressive strength.

28-Day Resistance Values

The final graph presents the 28-day compressive strength values for all mixes.

Analysis:

At 28 days, the 10% and 15% zeolite mixes show strengths close to the reference values, with some exceeding them. The 20% mix shows a noticeable reduction in strength, suggesting a possible optimal range for zeolite content between 10-15%.